The Sliding Motherboard Tray

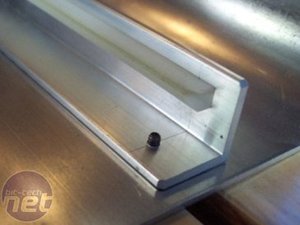

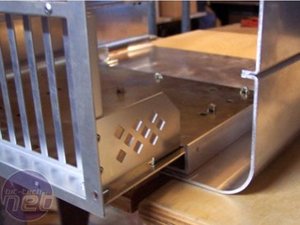

The motherboard tray was not a simple creation - not only did it have to slide out, it had to hold up a lot of weight while extended. Getting the motherboard tray to slide out was going to be an important part of this rig, and one I wasn't flexible on. Fortunately, the solution started with a very simple idea. Using an older Cooler Master tray and back plate, their slides were attached to aluminium angles which were simply fixed to the main pod's floor.

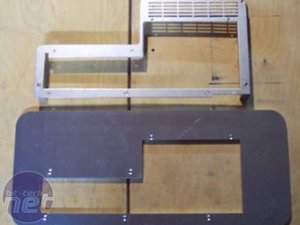

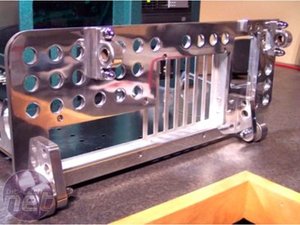

A second back plate was water cut from 1/4" thick aluminium and attached to the Cooler Master parts. It just has to be said here, water cutting is a great way to make nice inside cuts on aluminium. New motherboard stiffeners that mimic the front outriggers were also cut from 1/4" aluminium plate and added to support the increased weight.

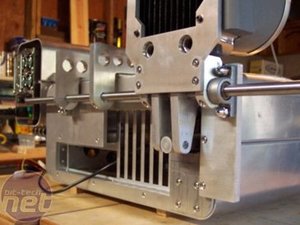

It was time to make all of the stuff up top pivot and it started with the fitting of some bearings and a shaft to the back plate. A series of brackets were cut from 1/2" aluminium plate for the various parts that were to move. The trick was making these parts with only a drill press, band saw and belt sander (there was no mill at the point that I did this).

Using a number of pieces of 1/2" thick aluminium flat bar, a mount was fabricated to support a 12V linear actuator that has a two inch stroke, capable of lifting about 120 pounds. It was carefully located with clamps on the back plate - space was at a premium, and there wasn't room for this to take up any more than it absolutely had to.

A hole was cut in the back plate for the actuator's shaft and the pieces started coming together. It was tested with a normal PC power supply and seemed to work well, lifting everything in about four seconds.

With a lot of weight on the back end, a couple of cam followers found on eBay were fit to a pair of brackets that aided stability. Finally, a series of holes, that would double as passages for airflow and coolant lines, were drilled into the back and all the parts were given a good polish. Even the bearings got some shine.

When some of the parts were assembled and laid out on the desk in order, they looked pretty crazy... certainly not like any computer parts we've seen before.

Want to comment? Please log in.